Synthetic Data

Automotive

Computer Vision

Synthetic Data

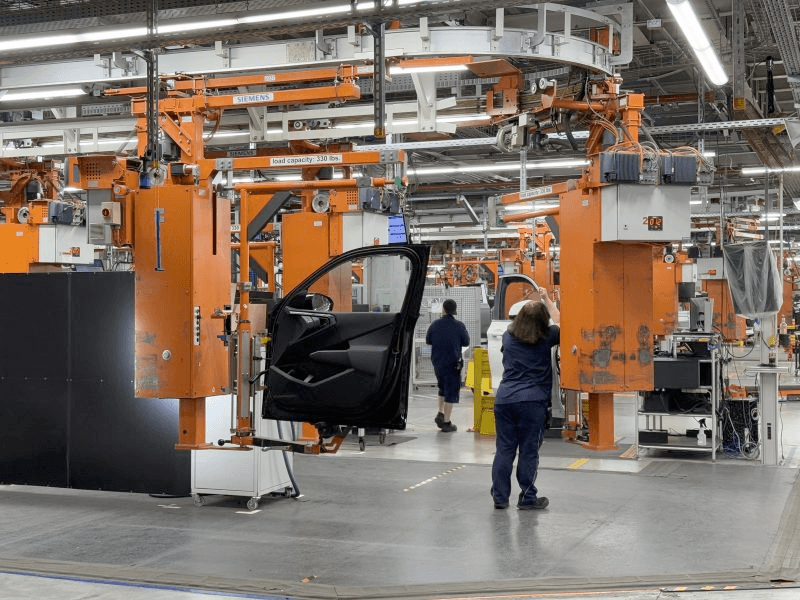

Production line with car doors, which are currently manually inspected after assembly

Motius developed a generative AI pipeline that can create large amounts of realistic image data, which show various defects and quality issues on door panels for cars. The customer (large automotive OEM) uses this synthetic data to train machine learning models, which can detect 99% of likely defects with only a very limited data set of 15 real photos.

- Our solution shortens the time to bring ML use cases into production, from months of manual data acquisition & labeling to only a few samples

- A model we trained on this data achieved 99% accuracy based on only 15 real images, while the rest were synthetic images

- This pipeline can generate labeled synthetic images from CAD files or other 3D models in a few hours

Technologies

- Blender for generating photorealistic synthetic data of possible defects from CAD assemblies

- YOLO as a Computer Vision model

Application at Bosch Rexroth

Synthetic data is even more useful when dealing with the high variety of products and customization options at Bosch Rexroth.

- Synthetic data can be generated from existing CAD models, or other product 3D renders

- Bosch Rexroth can catch more assembly issues and defects with specialized models trained on synthetic data, than with generic models